The ventilated facade, often referred to as a rainscreen cladding system, is one of the most efficient and sophisticated exterior wall construction methods available today. It represents a significant step forward from traditional plastered or direct-fixed claddings, offering superior thermal performance, moisture management, and aesthetic versatility. This comprehensive guide explores everything you need to know about this system, from its fundamental principles and numerous benefits to the specifics of cost, installation, and long-term durability.

What is a Ventilated Facade?

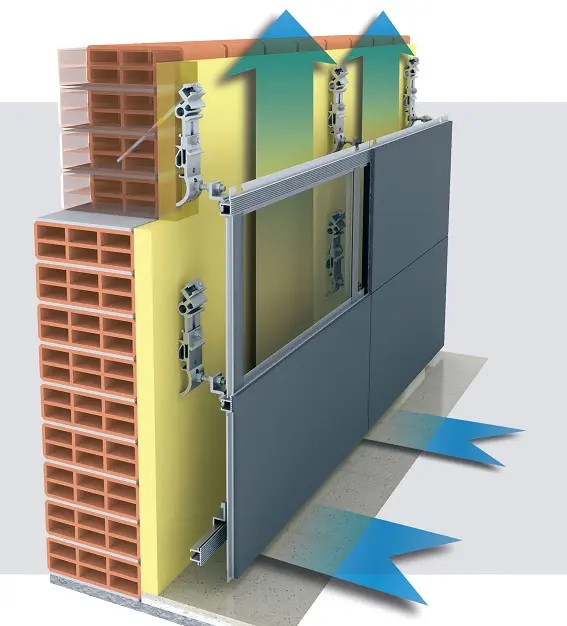

A ventilated facade is a multi-layered building envelope system that is fixed to the exterior wall of a building, leaving a continuous air gap (the ventilation chamber) between the insulation layer and the outer cladding material.

Core Components

The system typically consists of four main elements, working in concert:

- The Substrate Wall: The existing structural wall (e.g., masonry, concrete, or light-gauge steel).

- The Insulation Layer: Thermal insulation (mineral wool, EPS, PIR) is mechanically fixed or adhered directly to the substrate wall. This ensures the building’s thermal mass is on the « warm » side.

- The Supporting Structure (Substructure): An aluminum, stainless steel, or galvanized steel framework of brackets and rails is fixed through the insulation and into the substrate wall. This structure creates the required air gap and supports the external cladding panels.

- The Exterior Cladding: The visible protective layer, which can be made from a wide range of materials, including ceramic, stone, HPL (High-Pressure Laminate), metal, or composite panels.

The Principle of Ventilation (The « Chimney Effect »)

The defining feature is the air cavity. Air enters at the base of the facade and exits at the top. This phenomenon, known as the « chimney effect » or stack effect, provides three crucial functions:

- Moisture Removal: It continuously ventilates and dries the insulation and the inner wall surface, preventing condensation and mold growth.

- Rainscreen Principle: The outer cladding deflects the majority of wind-driven rain, while the air cavity helps manage any water that penetrates, draining it out.

- Solar Heat Reduction: In summer, the moving air dissipates heat absorbed by the outer cladding panels, reducing the thermal load transferred to the interior.

Key Advantages of Ventilated Facades

The initial investment in a ventilated facade is justified by a host of long-term benefits that significantly enhance a building’s performance, durability, and value.

1. Exceptional Thermal Performance and Energy Savings

By moving the insulation to the exterior, the system eliminates thermal bridging, which are paths of high heat flow that compromise a building’s energy efficiency. The continuous, thick insulation, combined with the cooling effect of the air gap, results in a more stable internal temperature, leading to substantial reductions in heating and cooling costs.

2. Superior Moisture Management and Building Health

This is the system’s most significant benefit. By preventing water penetration and actively drying the internal layers, a ventilated facade protects the building structure from degradation, rot, and moisture damage. This directly contributes to a healthier indoor environment by mitigating the risk of mold and mildew formation.

3. Acoustic Insulation

The multi-layered structure, particularly the mass of the cladding panels and the air gap, acts as an effective sound barrier, significantly reducing external noise pollution (traffic, construction, etc.) transmitted into the building.

4. Aesthetic Flexibility and Renewal

Ventilated facades offer virtually limitless design possibilities. They can accommodate almost any cladding material, size, texture, and color. For renovation projects, it completely transforms the building’s appearance without disruptive internal work.

5. Increased Lifespan and Low Maintenance

The components are highly durable and protected from direct weathering. The cladding panels are easy to replace individually if damaged. The overall system is designed to have a lifespan often exceeding 50 years, with minimal maintenance required beyond occasional cleaning.

Installation Process and Considerations

Installing a ventilated facade is a systematic process that requires specialized knowledge and adherence to strict technical standards.

Step 1: Substrate Preparation

The existing wall is inspected, cleaned, and repaired. Structural integrity is paramount, as the facade’s entire weight will be transferred to this wall.

Step 2: Fixing the Brackets and Insulation

- Bracket Installation: Specialized anchor brackets are fixed mechanically through the wall. These brackets must be thermally broken (e.g., using a non-conductive pad) to minimize heat loss.

- Insulation Installation: Insulation boards are tightly fitted and mechanically secured over the brackets. Proper alignment is critical to ensure a continuous thermal blanket.

Step 3: Installing the Supporting Structure (Rails)

Vertical and/or horizontal aluminum rails are attached to the brackets. The precision of this step is vital, as the rails must create a perfectly plumb and level plane, regardless of any irregularities in the underlying wall. The air gap must be consistent, typically between $20 \text{mm}$ and $50 \text{mm}$.

Step 4: Installing the Cladding Panels

The exterior panels are fixed to the rails using various methods depending on the material:

- Visible Fixing: Screws or rivets that are exposed (often color-matched).

- Concealed Fixing: Specialized clips, undercut anchors, or structural adhesives that hide the fixing mechanism, providing a seamless finish.

Key Installation Rule: Proper detailing around window/door openings, corners, and the top/bottom of the facade is essential to ensure continuous ventilation, drainage, and weather tightness.

Ventilated Facade Cost Analysis

The price of a ventilated facade system varies dramatically based on three primary factors: material choice, system complexity, and project scale.

A. Factors Affecting Price

| Cost Factor | Description | Impact on Price |

| Cladding Material | Ceramic, HPL, fiber cement, metal, stone, wood. | Most significant factor. Natural stone is highest; fiber cement is typically lowest. |

| Substructure | Aluminum systems are more expensive but lighter and rust-proof than steel. | Mid-range impact. |

| Insulation Type | Mineral wool is standard; high-density, high R-value materials cost more. | Lower impact, but necessary for performance. |

| Fixing Method | Concealed fixing systems (undercut anchors) are substantially more expensive than visible screws/rivets. | Mid-to-high impact. |

| Building Height/Shape | Taller buildings and complex geometries require specialized equipment, engineering, and labor. | Significant impact on total project cost. |

B. Estimated Price Range

A general installed price range (including materials, insulation, substructure, and labor) for a standard commercial or residential project typically falls between €150 and €450 per square meter ($160 to $480 per square foot).

- Lower End (€150–€250/m²): Simple design, fiber cement or basic metal panels, visible fixing.

- Mid-Range (€250–€350/m²): HPL or quality ceramic panels, robust aluminum substructure, mix of visible and concealed fixing.

- High End (€350–€450+/m²): Large format natural stone, intricate terracotta, full concealed fixing, complex geometry, premium insulation.

Lifespan and Maintenance

One of the most compelling arguments for a ventilated facade is its remarkable durability and longevity.

Expected Lifespan

The lifespan is often divided into two categories:

- System Life (Substructure & Insulation): The structural components (brackets, rails) and the insulation are typically warrantied and expected to last 50 to 100 years—the life of the building itself—because they are fully protected from UV light and weather exposure.

- Cladding Panel Life: This varies by material, but most high-quality cladding panels (ceramic, HPL, metal) are guaranteed for 20 to 50 years before potential fading or material fatigue might necessitate replacement for aesthetic reasons.

Minimal Maintenance Requirements

The self-ventilating nature of the system is inherently low-maintenance.

- Regular Cleaning: The primary maintenance involves periodic cleaning of the exterior panels, which is material-dependent (e.g., occasional washing for ceramic or metal).

- Inspection: Annual visual inspections should focus on the integrity of the sealant around openings and the drainage outlets at the base.

- Repair: Unlike traditional systems where a failure in one area can lead to widespread damage, individual damaged panels in a ventilated facade can be easily removed and replaced without affecting the rest of the system, minimizing repair costs.

Conclusion

The ventilated facade is more than just a decorative cladding; it is a high-performance, sustainable building technology that provides a robust and intelligent solution to managing heat, moisture, and acoustics. While the upfront cost is higher than conventional plaster or EIFS (Exterior Insulation and Finish System), the facade’s ability to drastically reduce energy consumption, minimize maintenance, and guarantee the long-term health and integrity of the building envelope provides a superior return on investment over its extended lifespan. For architects, developers, and building owners looking for a blend of striking aesthetics and peak functionality, the ventilated facade is the optimal choice for modern construction and renovation.