In recent years, ventilated facades have become one of the most influential architectural and technical innovations in the industrial construction sector. Whether it is for factories, logistics centers, public buildings, commercial facilities, or renovated infrastructures, this system is rapidly becoming the preferred exterior cladding solution worldwide.

But why exactly are ventilated facades gaining such dominance? What makes them more efficient, durable, and cost-effective than traditional wall systems or simple exterior painting?

This article explores the key reasons why ventilated facades are now considered the #1 choice for large industrial projects — focusing on efficiency, durability, sustainability, and long-term performance.

1. Superior Thermal Performance and Energy Efficiency

One of the main reasons ventilated facades are widely used in industrial buildings is their exceptional thermal performance.

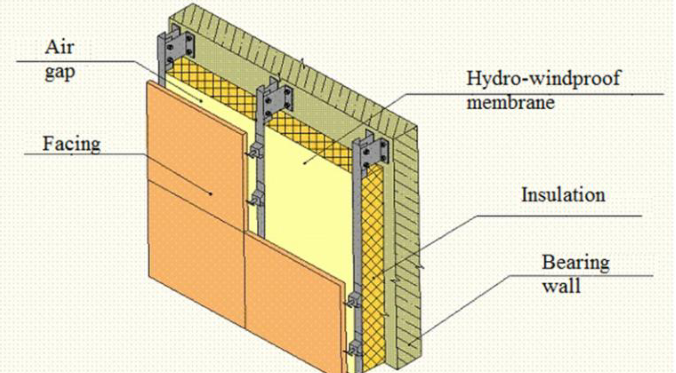

The construction includes an external cladding layer (such as composite panels), a ventilated air gap, and an insulated wall. This design allows air to circulate naturally, creating a “chimney effect” that regulates interior temperature.

Key benefits include:

- Reduced heat transfer through the building envelope

- Lower energy consumption for heating and cooling

- Better regulation of indoor temperature

- Significant reduction in thermal bridges

For large industrial structures, where temperature control is essential to protect equipment, production processes, and stored materials, the energy savings are substantial. Many companies report up to 30–40% reduction in energy costs after installing a ventilated facade system.

2. Extended Durability With Minimal Maintenance

Ventilated facades are designed to protect buildings against harsh environmental conditions such as UV radiation, humidity, strong wind, rain, and temperature fluctuations.

Because the cladding layer does not come into direct contact with the structural wall, moisture cannot accumulate, and the building envelope remains dry and stable.

Why this matters in industry:

- Industrial buildings often cover large surfaces exposed to the environment.

- Traditional paints deteriorate quickly, requiring frequent repairs.

- Ventilated facades can last 40 to 50 years with minimal replacement.

- They provide stronger mechanical resistance against shocks and vibrations.

This durability explains why many factories, logistics centers, refineries, and warehouses now prefer composite or aluminum panel ventilated facades instead of traditional painted walls.

3. Enhanced Aesthetic Value and Modern Appearance

Today’s industrial companies seek not only functionality but also a modern and professional appearance. Ventilated facade systems offer a wide variety of aesthetic possibilities:

- Dozens of color options

- Metallic, matte, glossy, and textured finishes

- Custom shapes and cutting possibilities

- 3D and curved designs

- Combination of multiple materials

This allows designers to transform old industrial buildings into impressive, modern structures without heavy demolition. A large facility equipped with high-quality composite panels immediately reflects:

- Professionalism

- Technological advancement

- Corporate sustainability

- Brand identity

For companies receiving clients, investors, or partners, the external appearance becomes a strategic asset.

4. Excellent Acoustic Performance

Ventilated facades significantly reduce external noise thanks to the combination of insulation and air cavity. This is particularly important for:

- Factories located near residential zones

- Industrial parks close to main roads

- Large workshops generating internal noise

- Offices integrated inside industrial buildings

A quieter environment improves employee comfort and reduces sound pollution for surrounding communities. As regulations become stricter, acoustic performance is becoming a priority for industrial construction.

5. Strong Contribution to Sustainable and Eco-Friendly Construction

Ventilated facades are highly valued for their environmental benefits:

- Reduced energy consumption

- Possibility of using recyclable materials (e.g., aluminum composite panels)

- Increased durability, reducing waste over time

- Minimization of CO₂ emissions in heating/cooling

- Compatibility with solar panels and green building standards

Many systems meet international certifications such as LEED, BREEAM, and HQE. For modern industries seeking to reduce their carbon footprint, ventilated facades offer a clear advantage.

6. Protection Against Humidity and Structural Degradation

Moisture is one of the biggest threats to industrial buildings. Over time, water infiltration can cause:

- Structural weakness

- Mold growth

- Rust and corrosion

- Degradation of concrete

- High maintenance costs

Ventilated facades prevent these issues by creating a continuous air circulation layer. The wall remains dry in all seasons, significantly extending the building’s lifespan and reducing long-term repair expenses.

7. Faster Installation and Reduced Production Interruption

Time is essential in industrial construction. Every day of interruption can result in significant financial losses. Ventilated facade systems offer:

- Fast installation

- Dry construction (no heavy wet processes)

- Easy panel replacement

- Minimal impact on internal operations

Panels can be installed even while the facility is operating, avoiding costly shutdowns. This is a major advantage over traditional renovation methods such as painting or plastering.

8. Adaptability to New and Existing Buildings

Ventilated facades are compatible with:

- New industrial projects

- Renovation of old factories

- Expansion of existing facilities

- Modification of corporate headquarters

They can be installed on concrete, brick, metal, and even old cladding systems. This flexibility allows companies to modernize infrastructures without rebuilding everything from scratch.

Conclusion

Ventilated facades have earned their place as the #1 solution for large industrial buildings due to their unmatched combination of energy efficiency, durability, aesthetic flexibility, and long-term economic performance.

In a global context where sustainability, cost optimization, and architectural quality are becoming essential, ventilated facades offer a modern, high-performance, and future-proof alternative to traditional exterior finishes.

Whether it’s to reduce energy bills, modernize an industrial image, protect the structure, or comply with new environmental standards, ventilated facades represent a smart investment for any large industrial project.